Moulding

The moulding of plastic and rubber components is the main service that D&G Moulding offers.

One of the company’s aims is to ensure that customers can access high-quality components without being restricted by large batch sizes – that’s why there’s no minimum quantity on production runs. This is particularly beneficial when developing and launching new products.

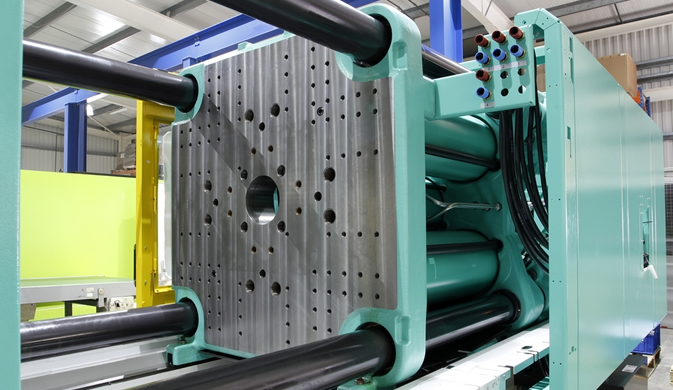

Using Arburg and Sumitomo Demag machine technology, D&G Moulding can ensure that the process developed for small production runs is repeatable, producing identical results on larger runs. Set-up data is stored and backed-up off-site ensuring that components are consistent in every batch.

D&G Moulding can apply logos and text to the component using transfer printing. Other supplementary services such as hot foiling, electroplating or ultrasonic welding are subcontracted at competitive rates.

Components can be assembled and packaged with full traceability. D&G Moulding then ship the components to the customer’s chosen destination.

Whether you're looking for expert advice, a prototype or a production run of any size, contact D&G Moulding today on +44 (0) 1420 549347 or email sales@dgmouldingltd.com